Sustainable Materials & Manufacturing

We started with the most basic unit of our fabric: the yarn. Made from the pulp of beechwood trees through a process called “biorefinery”, Lenzing TENCELTM Modal. Lenzing’s beechwood is sourced from sustainably managed forests and plantations. The fibers are compostable and biodegradable at the end of their life cycle, closing the material loop and creating natural circularity.

Reduced Environmental Impact

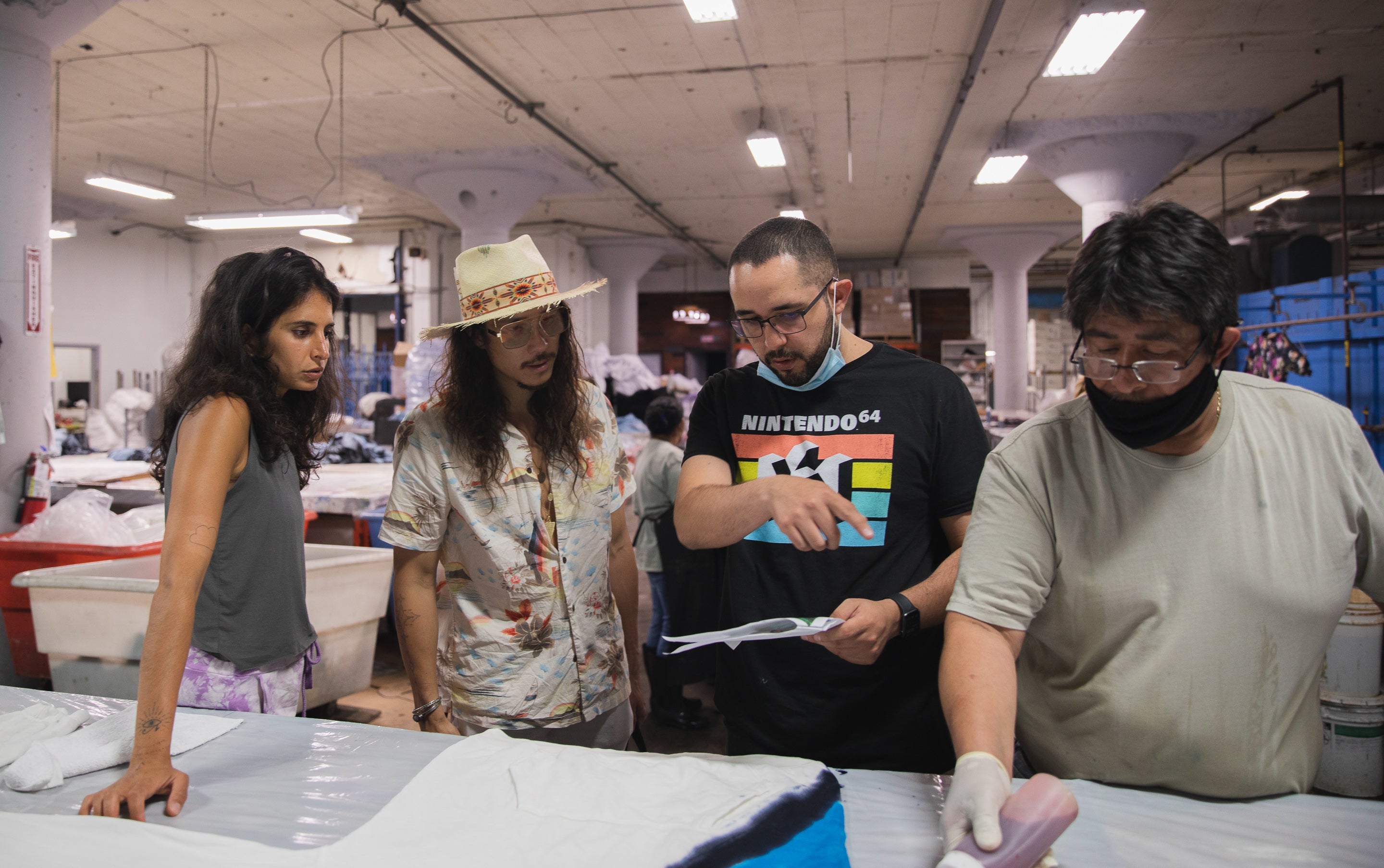

The reactive dyes used in Softwear’s products bond to the fabric’s molecules and become part of the clothing. This means we don’t have to wash and rewash garments to remove unfixed dye, and the color never fades. The initial dye process uses 30% less water, and requires no further processes after the first dye. Reactive dyes are the least irritating of dyes to wear since they don’t transfer to the wearer.

In an effort to cut down on our carbon footprint, we produce every single aspect of Softwear’s product in Los Angeles. Our hang tags, fabric manufacturer, cut and sew, and dye house are located within a 10 mile radius of each other.